This Seven 662 SLX immediately stood out when I spotted it on a rack of incoming bikes. We see plenty of carbon and titanium bikes come through TPC, but it's rare to come across a bike that combines the two materials in the way that the 622 SLX does.

This 2020 622 SLX uses a carbon head tube, top tube, down tube, seat tube, and seatstays which are all bonded to titanium lugs. These lugs have been machined and welded, and they even feature little number 7's that have been machined out to add a little extra flourish. The end result is a unique bike that's also pretty light, weighing only 16 lbs 4 oz for an ~X-large.

This 2020 622 SLX uses a carbon head tube, top tube, down tube, seat tube, and seatstays which are all bonded to titanium lugs. These lugs have been machined and welded, and they even feature little number 7's that have been machined out to add a little extra flourish. The end result is a unique bike that's also pretty light, weighing only 16 lbs 4 oz for an ~X-large.

The build on this bike is pretty blingy too with a gold Kogel Kolossos pulley cage, gold Chris King headset, and ENVE SES rims laced to Chris King hubs.

The build on this bike is pretty blingy too with a gold Kogel Kolossos pulley cage, gold Chris King headset, and ENVE SES rims laced to Chris King hubs.

I personally don't think the 622 SLX is particularly pretty or technologically exciting (though Seven fans might say it's both), but it's still an interesting bike. In trying to find an analogy to understand how I feel about it, I began to think that it's a bit like the DeLorean — a classic machine that is somehow both retro and futuristic at the same time.

Yeah? Maybe? Photo: Matt Blitz

Carbon tubes bonded to titanium lugs harken back to a time when framebuilders were still experimenting with how to properly build a carbon bike. The tube and lug method was already tried and abandoned by many other brands over 30 years ago.

Right now though, lugged carbon/Ti has made a bit of a comeback as one of the most cutting-edge construction methods in a surprising discipline: downhill mountain biking. This revival feels a bit like seeing the DeLorean's retro/futuristic styling getting reborn in the form of the new Cybertruck.

Perfecting Old Ideas

Seven began experimenting with lugged carbon in 1997. This makes sense since its core crew came from Merlin, which built John Tomac’s legendary Raleigh Carbon/Ti in the early ‘90s. Compare the two bikes and it’s clear that they share some DNA.

Tomac raced this Raleigh Carbon/Ti for a few years, but for whatever reason, this type of frame never really caught on in the world of XC mountain bike racing. Yeti, who built the predecessor to this bike, chose to abandon the concept and return to steel because it was simply too time consuming and difficult to produce frames with the technology at the time. As a result, steel and aluminum bikes would continue to dominate the market for another decade or more.

The Look KG 86. Photo: Look Cycles.

The Look KG 86. Photo: Look Cycles.

If we go back a bit farther in time, the 622 SLX also reminds me of another very famous lugged carbon bike — the Look KG 86. The KG 86 achieved legendary status when American Greg LeMond rode it to victory in the 1986 Tour de France. It was actually the first carbon bike to win the Tour! While this bike does look similar to Seven’s 622 SLX, it used aluminum lugs instead of titanium. The carbon tubes also had Kevlar woven into the carbon tubes for extra strength.

Again, this novel design didn’t catch on in road cycling either, despite it winning the biggest bike race in the world. A big issue was how flexy the frame was, a common problem with most early glued frames. It obviously didn't slow down a powerhouse like LeMond, but he would eventually achieve his next two Tour wins on stiffer steel race bikes.

The derailleur hanger is titanium and not replaceable. Seven says it's so stiff and strong though that they almost never get bent or broken.

The derailleur hanger is titanium and not replaceable. Seven says it's so stiff and strong though that they almost never get bent or broken.

Seven, on the other hand, has stuck with and perfected its carbon/Ti frames over the last 30 years. Its production methods are dialed, and the design has been refined over time to bring the performance in line with modern expectations.

To combat flex, Seven beef up the chainstays. While the KG 86 used carbon chainstays, the 622 SLX uses titanium. The lower backbone of the frame — the bottom bracket, chainstays, and rear dropouts — are all welded together to create a solid titanium unit, and chainstays themselves are one inch thick to further increase stiffness.

Combine this with larger diameter carbon tubes that use a more modern lay-up, and you get a stiff race bike that can accelerate and corner as well as many of today’s best monocoque frames.

It's All About Customization

The founders of Seven Cycles all worked together at Merlin Metalworks, one of the OG titanium bike builders from the ‘80s and ‘90s. After Merlin was bought and sold several times in quick succession and then relocated to Tennessee, the Seven crew decided to jump ship and start their own brand in 1997.

The founders of Seven Cycles all worked together at Merlin Metalworks, one of the OG titanium bike builders from the ‘80s and ‘90s. After Merlin was bought and sold several times in quick succession and then relocated to Tennessee, the Seven crew decided to jump ship and start their own brand in 1997.

From the beginning, they wanted to do things differently. The key for them was to “put the rider first.” This meant custom geometry and builds designed to suit each rider. Just look at Seven's design guide and fit worksheet and you’ll see the huge amount of options you have when ordering a new bike.

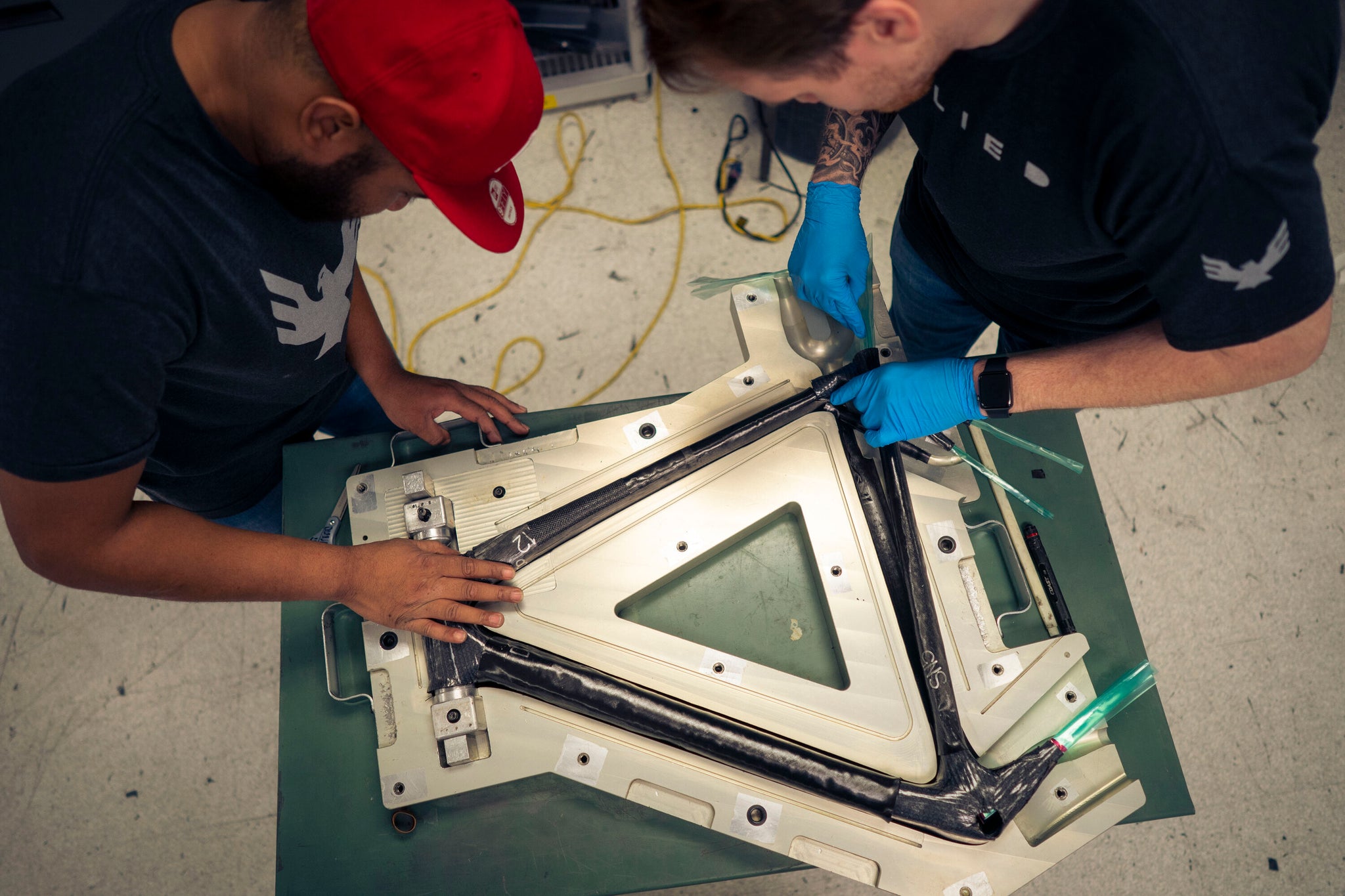

Laying carbon fiber in a frame mold. Photo: Allied Cycle Works.

Laying carbon fiber in a frame mold. Photo: Allied Cycle Works.

Most modern carbon bikes use monocoque frames that are created by laying carbon sheets into a mold. Not only does this create a light and strong frame, but it also allows engineers can mold the frames into complex and aerodynamic shapes and finely control how they flex in different directions to achieve specific ride characteristics.

There is, however, one major limitation with monocoque frames. Have you ever noticed that most bike brands only offer carbon frames in 5-7 sizes? That’s because one of the most expensive parts of creating a carbon monocoque is the mold and each frame size requires its own mold. Sizes have to be limited to keep costs reasonable. What happens then is that many riders can get caught in between sizes.

With custom steel and titanium frames, this isn’t an issue. A good builder will choose the desired tube length to create a frame that perfectly fits your dimensions. But what if you’re a rider who wants the weight, feel, and look of carbon fiber as well as custom geometry? That’s the niche bikes like the Seven 622 SLX are intended to fill.

With custom steel and titanium frames, this isn’t an issue. A good builder will choose the desired tube length to create a frame that perfectly fits your dimensions. But what if you’re a rider who wants the weight, feel, and look of carbon fiber as well as custom geometry? That’s the niche bikes like the Seven 622 SLX are intended to fill.

Lugged Carbon/Ti Is Making a Comeback

Rachel Atherton has been using a lugged carbon/Ti bike to nab wins and podiums. Photo: Bartek Wolinski / Red Bull Content Pool

Rachel Atherton has been using a lugged carbon/Ti bike to nab wins and podiums. Photo: Bartek Wolinski / Red Bull Content Pool

The vast majority of “regular” bike riders are still buying monocoque carbon frames or TIG welded aluminum or steel frames. Lugged carbon is a fairly small niche, especially carbon with titanium lugs. The Seven 622 is a bit rarer than even other lugged carbon bikes like Parlee’s Z-Zero or Colnago’s C68. Lugged bikes in general just don’t seem to appeal to modern roadies who value modern aesthetics or aerodynamics.

In the world of mountain biking, however, lugged carbon has been having a bit of a moment. This is largely due to Atherton Bikes. If you don’t know, the Atherton siblings, Dan, Gee, and Rachel, are the most successful family in downhill racing, with Rachel Atherton being one of the greatest DH racers of all time.

The lugged carbon/Ti AM.150. Photo: Atherton Bikes

The lugged carbon/Ti AM.150. Photo: Atherton Bikes

The Athertons started their own bike company in 2019 and have been building frames that use carbon tubes joined together using 3D-printed titanium lugs. This lugged construction means Atherton Bikes can offer a huge range of sizes as well as fully custom sizing.

This is ideal for a discipline where riders obsess over the minutiae of frame geometry far more than most roadies will. These lugged carbon Atherton bikes have gone on to take multiple World Cup Downhill wins and podiums, showing that there is something to them.

Bernard Kerr showing off Pivot's lugged carbon prototype. Photo: Pivot Cycles

Bernard Kerr showing off Pivot's lugged carbon prototype. Photo: Pivot Cycles

Another major brand, Pivot, has also been using lugged carbon with aluminum lugs to build prototype DH frames at its home base in Arizona. With frame designs in the world of gravity racing evolving rapidly, building a frame using lugged carbon allows them to rapidly prototype new designs to stay competitive.

The Frameworks lugged aluminu mprototype. Photo: Frameworks

The Frameworks lugged aluminu mprototype. Photo: Frameworks

While it uses aluminum tubes instead of carbon, Neko Mullaly’s Frameworks project has also recently been experimenting with lugged frames in an effort to reduce weight and create frames that are more precisely aligned and easier to build. Frameworks uses carbon rear ends, so I think we may potentially see a full carbon lugged prototype from them someday soon too.

While lugged carbon or lugged carbon/Ti bikes might have failed to gain a strong foothold in the road and XC racing worlds, the world of enduro and downhill mountain biking might be the place where it can really shine. The ability to easily customize geometry and sizing might be its biggest advantage.

Mountain bikers get very particular about things like stack and reach, head angles, bottom bracket height, wheelbase. For top riders, a change of a few millimeters can affect their performance (or at least their confidence). Lugged carbon gives manufacturers the ability to quickly dial in geometry, fit, and even suspension kinematics for individual riders, and maybe even specific race tracks.

Seven's 622m XX lugged carbon MTB. Photo: Seven Cycles

Seven's 622m XX lugged carbon MTB. Photo: Seven Cycles

If Seven wanted to, they could probably get in on all that hot lugged carbon action occurring in the downhill mountain bike world. They already build hardtail and full-suspension mountain bikes, including the 622m which is actually the mountain bike version of the 622 road bike. But if I had to guess, I’d say they’re probably not interested.

You keep doing you, Seven.

You keep doing you, Seven.

Seven is the type of brand that doesn’t really need to change or evolve. It doesn't deal with model years, expensive advertising campaigns, or race teams. Building a bike that fits a particular rider perfectly is all that matters.

Honestly, it’s always a surprise to even see a Seven come into TPC, because, to me, it’s the type of bike you buy to keep forever.